Uttam Energy: Unifying EPC with Dexciss ERP

Uttam Energy, an EPC manufacturer for biomass power plants, implemented Dexciss ERP to solve internal data silos.

The result was unified project costing, real-time production visibility, and efficient financial control across all operations.

Company Overview

Uttam Energy Limited is a premier EPC (Engineering, Procurement, and Construction) Solution Provider in the energy sector. With a strong focus on high-quality engineering and manufacturing, the company specializes in delivering turnkey projects for co-generation, biomass-based Independent Power Plants, and waste-to-energy solutions. Their operational scope involves complex, multi-phase contracts combined with in-house manufacturing of critical components, such as specialized boilers. This hybrid model necessitates precise coordination, robust quality control, and granular cost management across all project stages to ensure timely and budget-compliant delivery.

Customer Name:

Uttam Energy Limited (UEL)

Year of Establishment

2012

Headquarters

Pune, Maharashtra, India

Industry Sector

Energy & Power, EPC

Challenges

Prior to implementing Dexciss ERP, Uttam Energy faced several critical operational hurdles typical of project-driven manufacturing environments. These challenges stemmed from fragmented systems and manual processes, which hindered operational efficiency and financial visibility.

- Fragmented Cost Visibility: Difficulty in accurately capturing and attributing all direct and indirect project costs (materials, labor, subcontracts) to individual EPC contracts, leading to significant risk of project cost overruns and inaccurate margin calculation.

- Operational Silos: A lack of real-time integration between the shop floor (Manufacturing), inventory planning (Inventory), and vendor management (Purchase), resulting in frequent material shortages, inefficient production scheduling, and delays in project timelines.

- Complex Procurement: Managing a vast and specialized supply chain required a cumbersome manual process for vendor evaluation, contract management, and multi-level Purchase Requisition (PR) and Purchase Order (PO) approvals, slowing down crucial procurement cycles.

- Compliance and Auditing: Ensuring consistent adherence to stringent global quality standards (e.g., ASME/ISO) and providing clear audit trails for both quality control and financial compliance was manually intensive and error-prone.

Solution: Dexciss ERP Implementation

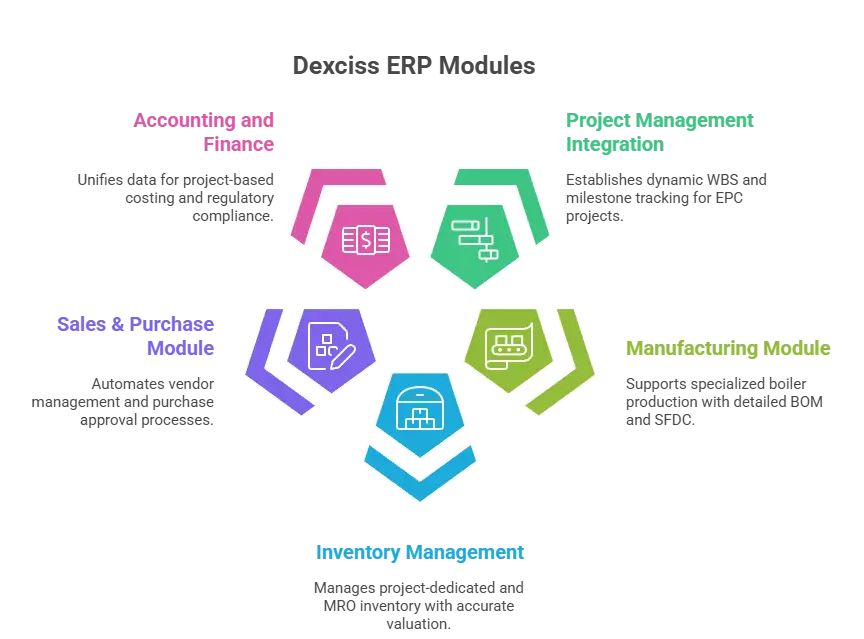

Uttam Energy Limited adopted the Dexciss ERP system as a single, integrated platform designed to unify its critical business functions. The implementation focused on deploying and customizing core modules to address the specific demands of EPC and project-based manufacturing:

- Project Management Integration: The module established a dynamic Work Breakdown Structure (WBS) for every EPC contract, directly linking project tasks, budgets, and resource allocation. It enabled milestone-based progress tracking and accurate Earned Value Management.

- Manufacturing Module: This module was tailored to support specialized boiler production, utilizing detailed Bills of Materials (BOM) and precise production routings. It implemented Shop Floor Data Capture (SFDC) for real-time tracking of labor hours and machine utilization, feeding directly into cost analysis.

- Inventory Management: The solution created segregated inventory classifications to manage project-dedicated stock versus general MRO (Maintenance, Repair, and Operations) inventory. This ensures material availability, optimizes reorder points, and maintains accurate stock valuation methods for project costing.

- Sales & Purchase Module: This provided a structured workflow for vendor registration, rating, and management. It automated the multi-level approval process for PR and PO generation, ensuring purchase decisions align with project budgets and timelines.

- Accounting and Finance: The system unified all operational data to enable Project-Based Costing, automatically generating accurate, real-time Project Profit & Loss statements, managing asset depreciation, and ensuring seamless compliance with local statutory regulations.

Results

The deployment of Dexciss ERP provided Uttam Energy Limited with the unified, data-driven platform required to enhance operational control and strengthen its market position, delivering measurable impact across the organization:

- Enhanced Project Profitability:

- Achieved real-time project-based costing, eliminating cost leakage and allowing management to make proactive adjustments to maintain profitability targets.

- Significantly reduced financial risk by gaining immediate visibility into budget versus actual expenditure.

- Improved Operational Efficiency:

- Accelerated procurement cycles due to the automated PR-to-PO workflow and improved vendor rating systems.

- Minimized production delays by ensuring timely material supply through integrated Inventory and Manufacturing modules.

- Superior Quality and Compliance:

- Digitalized all quality control checks and documentation in the Manufacturing module, ensuring strict adherence to international quality standards (ASME/ISO) with a clear, auditable trail.

- Strategic Decision Making:

- Management gained access to a single source of truth across all operational data, facilitating accurate forecasting, strategic planning, and faster, more informed business decisions.