Sumit Textiles: Transforming Manufacturing & Export with Dexciss ERP

Sumit Textiles, an export-focused textile manufacturer, relied on multiple systems and Excel for critical operations, including import/export tracking and production visibility.

With no structured manufacturing records or stock transparency, processes were manual and fragmented.

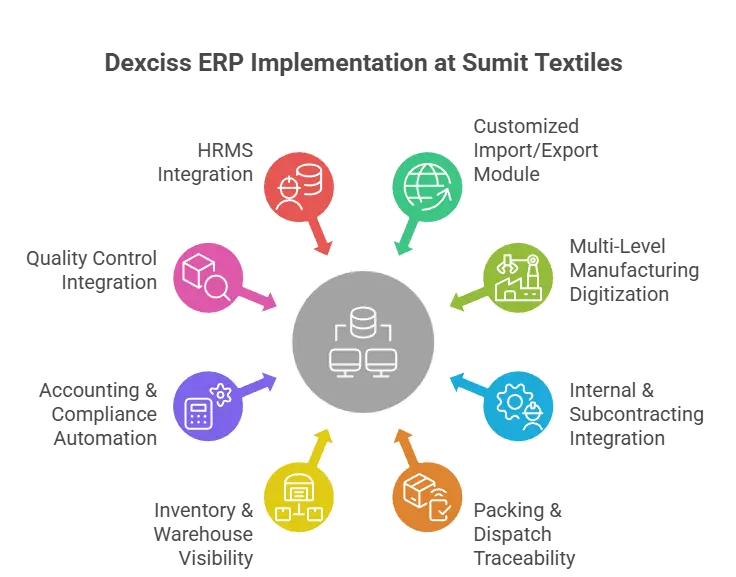

Dexciss ERP unified multi-level manufacturing, subcontracting, packing traceability, accounting, and GST compliance into one integrated platform — delivering real-time visibility and operational control.

Company Overview

Sumit Textiles is a Bhiwandi-based textile manufacturer and exporter specializing in premium cotton, linen, and blended fabrics. The company serves both domestic and international markets with high-quality shirting, yarn-dyed, jacquard, and specialty fabrics.

Operating in a competitive export-driven textile environment, Sumit Textiles manages multi-stage manufacturing processes including dyeing, cutting, stitching, tufting, finishing, and packing. The nature of operations demands strict quality control, precise inventory tracking, accurate export documentation, and seamless coordination between internal production and subcontracting partners.

Customer Name:

Sumit Textiles

Year of Establishment

2013

Headquarters

Bhiwandi, Maharashtra, India

Industry Sector

Textile Manufacturing & Export

Challenges

Prior to implementing Dexciss ERP, Sumit Textiles operated on multiple disconnected systems, with heavy dependence on Excel for critical processes. This resulted in limited visibility, manual coordination, and operational inefficiencies across departments.

- Disconnected Systems: Accounting and purchase operated in Tally, while manufacturing and export data were maintained separately, leading to fragmented reporting.

- No Import/Export Tracking System: Shipment documentation, transfer port management, and export records were handled in Excel, increasing risk and reducing traceability.

- Multi-Level Manufacturing Without Digital Control: Complex processes — dyeing, cutting, stitching, tufting, finishing, and packing — lacked structured job card tracking and production monitoring.

- Internal & Subcontracting Coordination Gaps: Limited visibility across internal manufacturing and third-party job work created material tracking and reconciliation challenges.

- No Real-Time Stock Visibility: Warehouse inventory and raw material consumption were not accurately tracked across stages.

- Manual Packing & Dispatch Tracking: Box-wise quantities, net weight, gross weight, and unit-level details were manually maintained.

- Compliance & Financial Integration Issues: GST filings (R1, R3B, BR1), supplier/custom payments, and GL postings required manual reconciliation.

- Limited Quality Control Traceability: Quality checks during receipt, job work stages, and dispatch were not systematically recorded.

Solution: Dexciss ERP Implementation

Sumit Textiles implemented Dexciss ERP as a fully integrated platform to streamline multi-stage textile manufacturing, export operations, accounting, and compliance. The implementation focused on digitizing core processes and eliminating manual dependencies:

- Customized Import/Export Module: A dedicated import/export module was developed to manage shipment tracking, transfer port documentation, export records, and linkage with sales and accounting — replacing Excel-based management.

- Multi-Level Manufacturing Digitization: Structured production workflows were implemented covering dyeing, cutting, stitching, tufting, finishing, and packing, with real-time job card and production plan tracking.

- Internal & Subcontracting Integration: The system unified internal manufacturing and third-party job work, ensuring raw material tracking, supplier coordination, and consumption visibility.

- Packing & Dispatch Traceability: Packing lists now capture box-wise quantities, net weight, gross weight, and unit-level details, directly linked to Delivery Notes and Sales Invoices.

- Inventory & Warehouse Visibility: Real-time stock tracking was enabled across raw materials, WIP, and finished goods, improving material planning and reducing discrepancies.

- Accounting & Compliance Automation: Automated GL postings, supplier/custom payments tracking, and GST reports (R1, R3B, BR1) were integrated with operational workflows for accurate financial control.

- Quality Control Integration: Quality checkpoints were embedded at receipt, job work stages, and dispatch to ensure consistent product standards.

- HRMS Integration: Employee management and payroll were integrated to support manufacturing operations and workforce tracking.

.

Results

The deployment of Dexciss ERP provided Uttam Energy Limited with the unified, data-driven platform required to enhance operational control and strengthen its market position, delivering measurable impact across the organization:

- End-to-End Manufacturing Visibility: Digitized multi-stage production with real-time job card tracking and improved coordination between internal and subcontract processes.

- Accurate Packing & Dispatch Control: Automated box-wise quantity, net/gross weight capture, and seamless linkage from Manufacturing → Delivery Note → Sales Invoice.

- Streamlined Import & Export Management: Replaced Excel-based tracking with a structured system for shipment documentation and transfer port monitoring.

- Real-Time Inventory Transparency: Improved raw material, WIP, and finished goods visibility across warehouses, reducing discrepancies and delays.

- Stronger Financial & Compliance Control: Automated GL postings and GST reporting (R1, R3B, BR1), ensuring accurate reconciliation and statutory compliance.

- Integrated Quality Monitoring: Embedded quality checks at receipt, production stages, and dispatch, enhancing product consistency and audit readiness.

- Single Source of Truth: Connected manufacturing, accounting, export, and HRMS into one system — enabling faster, data-driven decisions.