Food manufacturers in the USA face a complex mix of challenges, from maintaining strict compliance with FDA regulations to managing intricate supply chains and ensuring product consistency. Juggling these demands while striving for efficiency and profitability can feel like an impossible task. This is where a modern, robust ERP system becomes not just a tool, but a necessity.

For many, ERPNext has emerged as a powerful, open-source platform. But can it truly address the unique and demanding requirements of the food manufacturing sector? Let's explore how ERPNext for food manufacturing can be tailored to meet the needs of mid to large-scale operations in the United States, offering a comprehensive solution for everything from formula management to lot traceability and beyond.

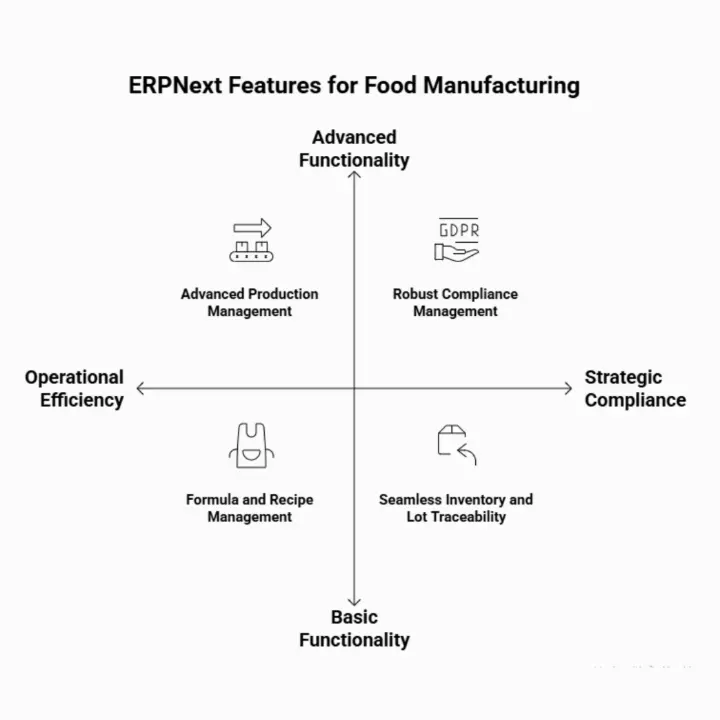

Key ERPNext Features for Food Manufacturing

An effective food manufacturing ERP needs to be more than just a standard business management system. It must be built with the industry's specific workflows in mind. Here's a look at how ERPNext, when customized for this sector, handles core processes.

Formula and Recipe Management

In food production, your recipes are your intellectual property. A solid system must allow you to manage, edit, and version control every formula. It should also track material substitutions, manage packaging components, and provide real-time formula costing. Imagine being able to instantly see how a change in a single ingredient affects the final cost of a product. This capability is vital for maintaining profitability. The right ERP solution can help you compare physical properties, manage loss factors, and track intermediate characteristics of your products.

Advanced Production Management

The journey from raw ingredients to finished product is a complex one. The right ERP for batch process manufacturing needs to support advanced models like SuperBatch™ or Runs. It must handle different types of production, whether you're performing contract manufacturing for a client or managing your own product lines. A flexible system allows you to manage both Make-to-Order (MTO) and Make-to-Stock (MTS) manufacturing. A feature like an Anytime Batch Sizing Wizard is a huge time-saver, letting you size a batch based on target output, material shortages, or available materials.

For food producers, dealing with allergens, kosher, or halal batches is a non-negotiable part of the process. Your system should allow you to create specific batches with these considerations in mind. Additionally, it should handle the complexities of fixed input/variable output scenarios, allow you to rework excess product back into inventory, and even generate labels with supplement facts, ingredients, and allergen warnings directly from the system.

Comprehensive Quality Control (QC)

Quality is paramount in the food industry. Your ERP system must be a central hub for all QC activities. This includes creating inspection plans, defining QC tests, and setting tolerance values. The ability to use mobile QC capture allows your team to perform checks right on the factory floor. Critically, the system should be able to restrict further processing if a QC test fails, ensuring no substandard product moves forward. The ERP should assign QC statuses to inventory and be able to generate a Certificate of Analysis (COA) for every batch, as well as analyze historical QC results to spot trends. Managing deviations, non-conformance, and adverse event reporting is also essential for maintaining standards and handling any issues that arise.

Seamless Inventory and Lot Traceability

Effective inventory management for food manufacturers is about more than just counting stock. It's about ensuring safety, compliance, and efficiency.

Advanced Inventory Management:

With an ERP, you can manage inventory across multiple warehouses and locations, and use various units of measure (UoMs). The system should support different costing methods like FIFO (First-In, First-Out), LIFO (Last-In, First-Out), and FEFO (First-Expired, First-Out), which is particularly critical for perishable food items. Integration with physical properties from databases like the USDA and the ability to track inventory based on QC status are also key features.

Lot Traceability

This is arguably one of the most important aspects for any food producer in the US. The system must provide full forward and backward traceability. This means you can trace a lot from its raw materials all the way to a customer's shipment, or trace a faulty product back to its original raw material supplier. This capability is essential for quick and effective product recalls, a process that can be costly and reputation-damaging if not handled efficiently. The system should track all lot-related transactions, shipments, and QC data to ensure a seamless audit trail.

Compliance, Planning, and Financial Management

Staying compliant and financially sound requires a system that can handle the administrative burden with ease.

Robust Compliance Management

The US food industry is heavily regulated. An ERP system must be a partner in compliance. It should track ingredients for allergen, organic, Kosher, and Halal status. It should also help you comply with a wide range of regulations, including FDA, GMP, and GFSA. The system should assist with managing chemical compliance (REACH, HAZMAT), and regulations like 21CFR Part 11. It should have the ability to generate essential reports like FDA audit reports and Nutritional Panels directly, saving time and reducing the risk of error.

Integrated Planning

Efficient production planning is the cornerstone of a successful manufacturing business. An ERP should support both Master Production Scheduling (MPS) and Material Requirements Planning (MRP). This allows you to plan demand and supply over time, run what-if scenarios, and automatically convert production plans into purchase or production jobs. This functionality is crucial for avoiding stockouts and production delays.

Comprehensive Costing

Accurate costing is vital for profitability. An ERP should be able to calculate costs using different methods (Last, Standard, Average). It should also account for formula loss and actual yield, and even include labor and overhead costs. Features like what-if costing and actual vs. expected cost comparison give you the tools to analyze and optimize your processes. The ability to roll up costs from sub-formulas to the final product provides a clear picture of your true expenses.

How ERPNext is a Suitable Choice for Food Manufacturers

While ERPNext is a powerful open-source platform, its strength for a specific industry like food manufacturing lies in its adaptability. A tailored solution built on ERPNext's framework can provide the deep industry-specific functionality needed by US manufacturers.

Why choose a custom-built ERP on ERPNext?

- Unlimited Licenses at Zero Software Cost: The open-source model means you can scale your team without incurring additional licensing fees. This is a significant advantage for growing companies.

- Deep Customization: Unlike off-the-shelf ERPs, a system built on ERPNext can be customized to your specific workflows. This means the software adapts to your business, not the other way around.

- User-Friendly Interface: The best ERP systems are those that are easy to use. A well-designed UI, like the one found in ERPNext-based systems, reduces training time and increases user adoption. Features like the Awesome Bar for quick search and navigation make daily tasks simple.

- End-to-End Automation: An effective ERP system automates the flow of information across all departments—from purchase to production to sales—reducing manual data entry and minimizing errors.

Final Thoughts

Choosing the right ERP is a crucial decision for any food manufacturer aiming for sustained growth and operational excellence. The challenges of the US market—from rigorous compliance requirements to managing a fast-paced production environment—demand a solution that is both powerful and flexible.

While the open-source nature of ERPNext provides a solid foundation, a custom-built solution that leverages its strengths to address the unique needs of the food industry is where its true value lies. Solutions like Dexciss ERP, which is built on ERPNext, are specifically designed to address these complex challenges. With its emphasis on unlimited licenses, an intuitive UI, and deep industry-specific modules for formula management, traceability, and compliance, it offers a robust and cost-effective solution for mid to large-scale manufacturers in the USA. By adopting an advanced ERP system, you can transform your operations, enhance compliance, and secure a competitive edge in the market.

Ask us for your ERPNext project cost estimation?

Frequently Asked Questions about ERPNext for Food Manufacturing

Q: How does an ERP system help with food safety compliance in the US?

An ERP system provides a centralized way to track and manage all aspects of food safety. This includes lot traceability for quick recalls, compliance reporting for agencies like the FDA, and automated quality control checks at every stage of production. It helps you maintain a secure, auditable record of all processes.

Q: Can ERPNext handle complex recipes with many ingredients?

Yes, a customized ERPNext for food manufacturing is built to handle complex formulas. It can manage multi-level bills of material (BOMs), track material substitutions, and even version control formulas as they are modified. This ensures that every team member is working with the most up-to-date recipe.

Q: What is the benefit of integrating sales and production data?

By integrating these modules, you can use sales forecasts to drive production planning. The system can automatically convert sales orders into production jobs, ensuring you produce what's needed to meet demand. This helps prevent overproduction and stockouts, optimizing inventory levels and improving customer satisfaction.

Q: Is it possible to manage multiple physical properties of a product?

Yes. An advanced ERP can integrate with databases like the USDA to store and manage multiple physical properties of a product, such as protein content, fat percentage, or moisture levels. This data can then be used for QC reporting, nutritional panels, and other key documentation.

Q: How does an ERP help with cost management for food products?

An ERP provides real-time costing by factoring in raw material prices, labor, overhead, and even loss factors. It allows for what-if costing scenarios to evaluate profitability changes and provides detailed reports comparing actual costs to planned costs. This visibility is crucial for making informed business decisions.

ERPNext for the US Food Manufacturing Industries: A Fresh Look at Efficiency